Prototype Wheels

PROTOTYPE WHEELS

Our CNC machines can turn blank alloy into beautiful works of art, giving the customer the assurance of excellence.

For all the vehicle production stages, from the most aesthetic and primary stage of conception to the end road test wheel, BRAID guarantees quality, fineness and reliability.

RESIN MODEL HOLDER

Type of wheels made only for laboratory static car or for very low speed, but able to mount real tyre in running conditions.

These are made with a thin metal sheet, fixed at the flat centre, with maximum outer diameter, to allow an easily fitment of the customer's resin design model.

Available from 10” to 26” diameter, in any width, offset and PCD.

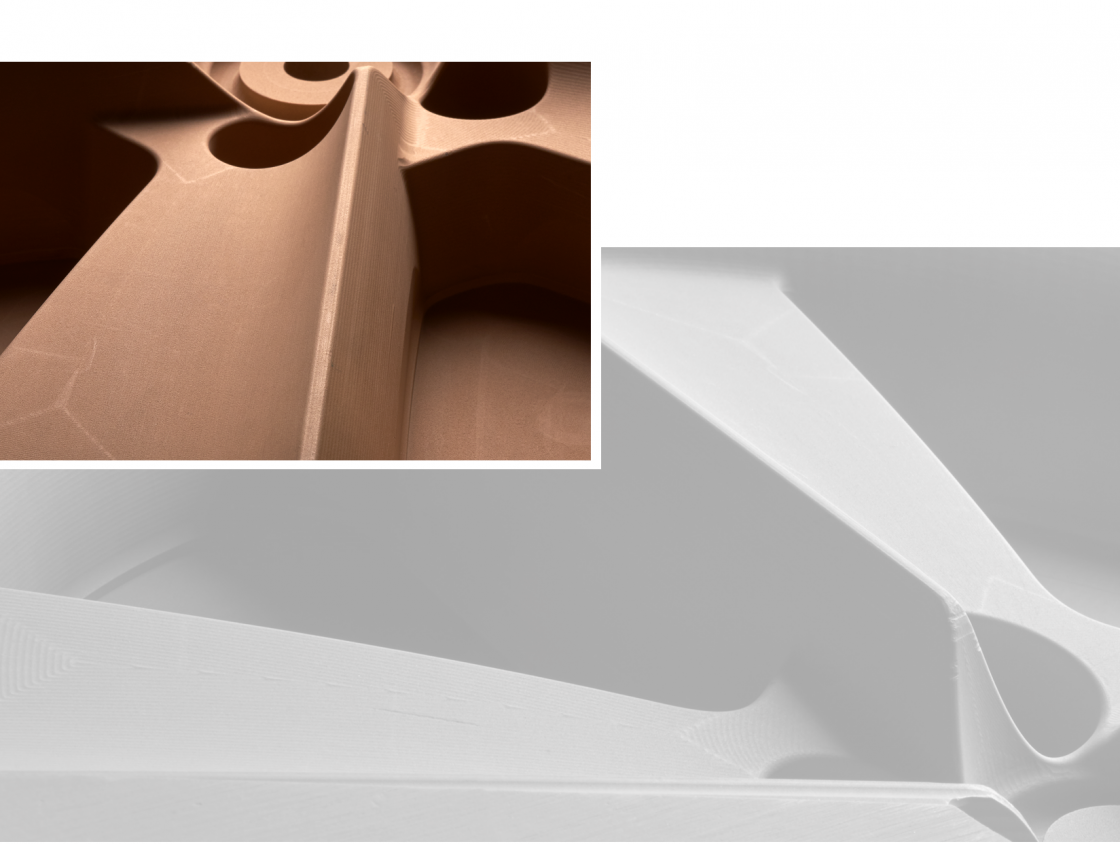

RESIN MODEL

Using CAD CAM software, CNC turning and milling machines, BRAID can manufacture any wheel design from a special resin block, enabling our customers to examine physically 3D prototype models.

It makes it much easier, and cheaper, to visualize a wheel style on the vehicle, and allows customers to review and modify their design prior to final product approval.

These can be tailored and finished to the exact requirements and colour requested by the customer.

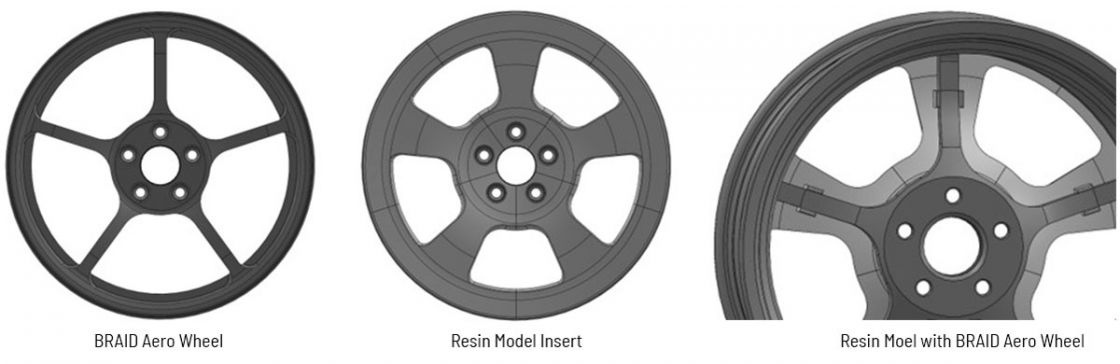

AERO WHEELS

Base wheels for early aero-testing rapid prototyping, to be used during wind tunnel testing, with resin inserts mounted on the spokes. Therefore, the wheels spokes are as thin as possible, still with enough strength to withstand the load cases of a wind tunnel testing.

- Thin Spokes to increase the design freedom for the Resin insert

- Spokes geometry compatible with snap-fit fastening design

- Front Face of the wheels is machined following costumers instruction to give space for the Resin insert

- Base Aero wheel is designed to withstand the strength and fatigue loads during wind tunnel testing

- Base Aero Wheel can be customised at costumer's specifications and requirements

- Resin Model Insert can be produced according to the Customer's 3D CAD drawing and Personalised Finish

Available in any diameter, width, offset and PCD. Minimum quantity to order: from 1 pcs

PROTOTYPE WHEEL

A unique experience of a unique wheel for the customer that wants to stand out from the crowd and express their own personality.

Saving the expensive tooling and moulding cost, we can offer a totally functional and full machined wheel, each differently, detailed and engineered with the outmost precision, and milled from a unique design project.

Our racing DNA and technological know-how adapts perfectly to offer the best service to our customer where knowledge and style are combined together to guarantee top performance and absolute quality.

Minimum quantity to order: from 1 pcs

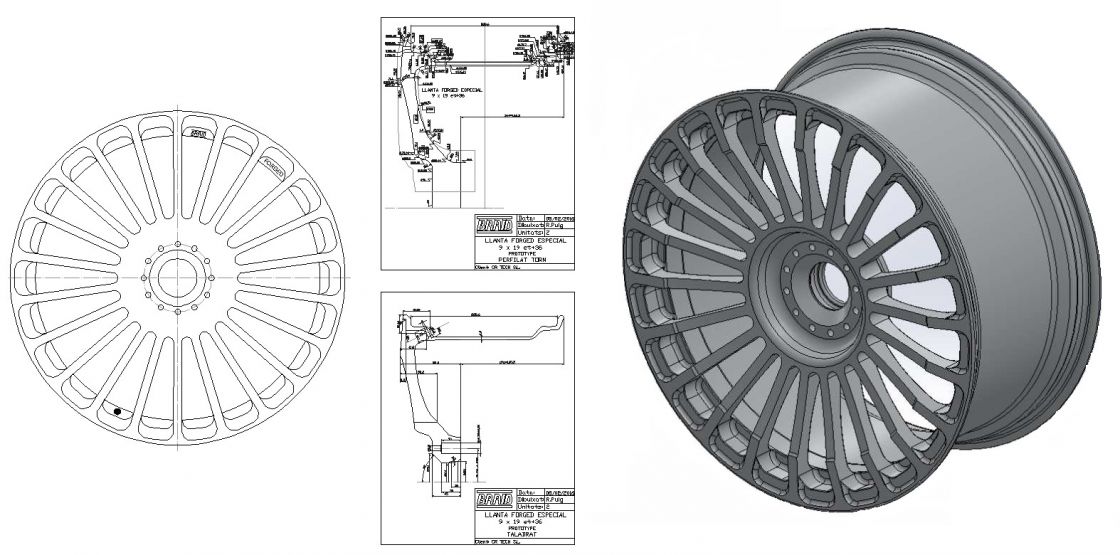

DYNAMIC TEST WHEEL

Specific wheels to allow vehicle dynamic test, tyre test, wind tunnel test, and other. The most important is to produce a Wheel with some technical characteristics, where the design is not as important, to allow the customer to test their vehicle.

Usually we use Forging Process because of its excellent material properties, which combined with the low mass of the wheel, delivers sporty driving performance and better braking characteristics. But we also use standard cast wheels with the final customer requirements

With this process we can adapt to customers requirements such as diameter, width, offset, PCD, weight, calliper clearance, special tire bead seats profile, etc ..

Minimum quantity to order: from 1 pcs

WHEELS FORCE TRANSDUCERS

The hub adapter connects the WFT to the vehicle. It can be used for different types of vehicles, as long as the bolt circle and the wheel offset are the same. With just a few hub adapters, an entire vehicle fleet can be covered.

As with a conventional rim, the rim adapter serves as a mounting for the tyre.

The rim adapter is not directly specific to the vehicle, but depends on the tire. This allows it to be used on different vehicles with the same tire size.

Minimum quantity to order: from 1 pcs

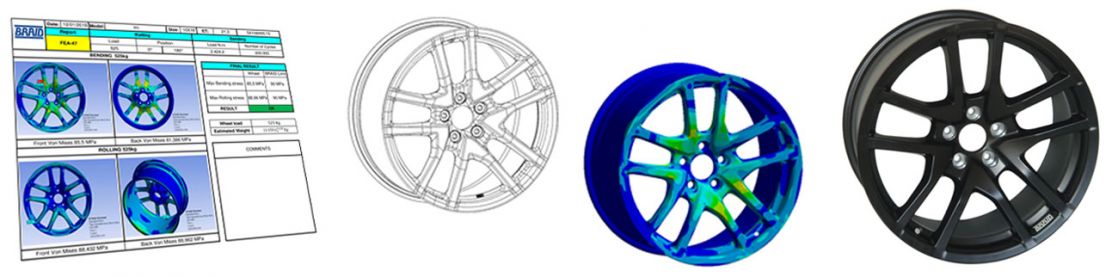

MASS PRODUCTION WHEELS

Based on design sketches or drawing from the customer that already show important individual wheel features, 3D computer models are developed using state-of-the-art IT systems

Computer simulation accelerates and optimises the development process and provides the basis for the first prototypes. After extensive testing, appropriate adjustments made and exact surface finish and colour selected, the new wheels goes into series production. For perfect, long-lasting and light alloy wheels we use top quality casting or forging blanks.

Minimum quantity to order: from 100 wheels.

FEA – FINITE ELEMENTS ANALYSIS

With FEA we simulate all the forces applied on the wheel such as Fatigue and Bending, in order to ensure that the wheels passes strength and stress tests.

LABORATORY TESTS

BRAID can carry all physical tests on a wheel inside our lab test. A team of engineers are at working every day, carrying all type of test such as cornering, rolling, impact, and transferring all the experience acquired in more than 40 years of racing to the service of our costumers.